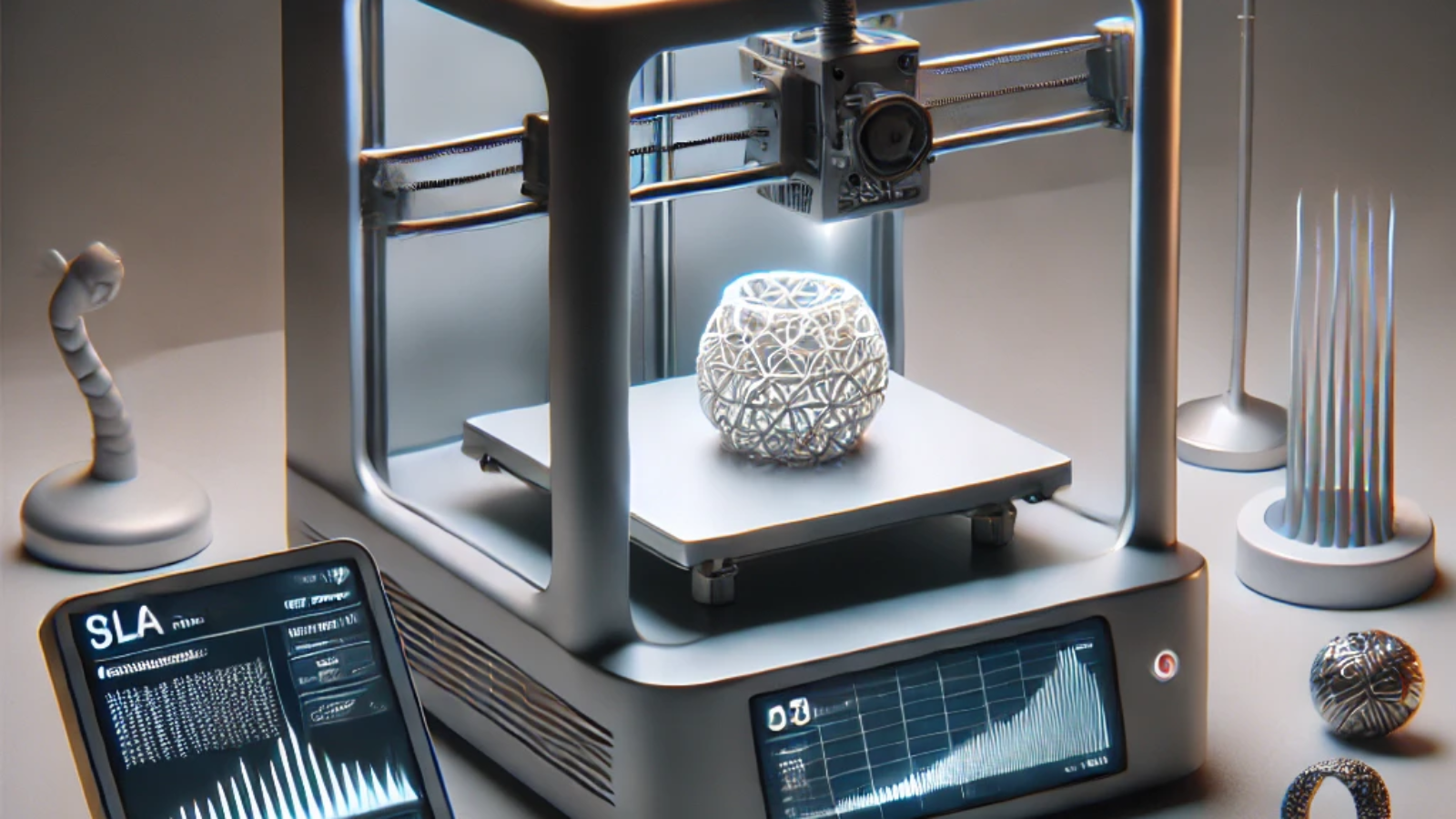

Once the design is approved, it transitions into the manufacturing phase using SLA (Stereolithography) 3D printing technology. This process represents the future of jewelry production, blending precision, efficiency, and innovation.

Why SLA 3D Printing?

- High Precision: SLA printing uses a laser to solidify liquid resin layer by layer, achieving exceptional detail and accuracy.

- Rapid Prototyping: Designs can be quickly converted into physical prototypes, allowing clients to inspect the piece before final production.

- Cost-Effectiveness: By minimizing material waste and speeding up production, SLA printing reduces costs without compromising quality.

The Manufacturing Process:

- Preparation: The approved MatrixGold design is uploaded to our SLA printer, where it’s converted into a highly detailed resin prototype or mold.

- Printing: The printer uses UV lasers to solidify each layer of resin with precision, ensuring that even the most intricate patterns are accurately reproduced.

- Post-Processing: Once the print is complete, the prototype is cleaned and cured, ready for the next stage of production.

SLA 3D printing not only accelerates the manufacturing process but also ensures that every piece meets our exacting standards of quality.

Leave a Comment